Removing Iron and Manganese In Water

Also see : Iron and Manganese explained

Polyphosphate Treatment

Polyphosphate Filters

Polyphosphates react with dissolved iron and manganese by trapping them in a complex molecule that is soluble in water. As a result the iron and manganese are not available to react with oxygen and precipitate. Polyphosphates can be fed into the water system with controlled injection equipment. Polyphosphates are not stable at high temperatures. If water is treated prior to heating in a water heater, the polyphosphates will release iron and manganese in the heater as they break down. The released iron and manganese will then react with oxygen and precipitate.

Polyphosphate treatment is a relatively cheap way to treat water for low levels of iron and manganese. Depending on the type of polyphosphate used, water with 1 to 3 ppm of iron can be adequately treated.

Ion Exchange - Softening

Water Softeners

Comprehensive water softener calculator

Soluble iron and manganese iron and manganese dissolved in water can be exchanged for sodium on an exchange resin or zeolite This process of iron and manganese removal is the very same ion exchange process that removes hardness or calcium and magnesium. Iron and manganese are removed during normal operation of the water softener. They are later removed from the exchange medium along with calcium and magnesium during regeneration and backwashing. Some water softeners are capable of adequately treating water having iron up to 10 ppm. However, others are limited to treating water with iron no greater than 1 ppm. If iron and manganese removal is desired in addition to hardness, the manufacturer"s recommendations should be checked.

One of the disadvantages of depending on ion exchange for iron and manganese removal is precipitation by oxygen. Some of the precipitate becomes tightly bound to the exchange resin and over time reduces the exchange capacity by plugging pores and blocking exchange sites. If iron bacteria are present, the problem is even worse. Also, if suspended particles of insoluble forms of iron or manganese are present in the water prior to softening, they will be filtered out on the resin and cause plugging. Suspended iron and manganese should be filtered out before water enters the softener.

A clogged water softener can be cleaned by acid regeneration if the unit is made to withstand acid corrosion. The manufacturer should be consulted before this is attempted. The problem with iron bacteria can be eliminated by chlorinating; Refer to the Chlorination circular in the Treatment Systems for Household Water Supplies series. And filtering the water at some point before it reaches the softener. As long as levels of iron and manganese in the water do not exceed the manufacturers recommendations, iron and manganese clogging should not be a significant problem. When iron and manganese levels are higher than recommended by the manufacturer, iron and manganese removal will be necessary prior to softening.

Greensand Adsorptive/Oxidative Filtration

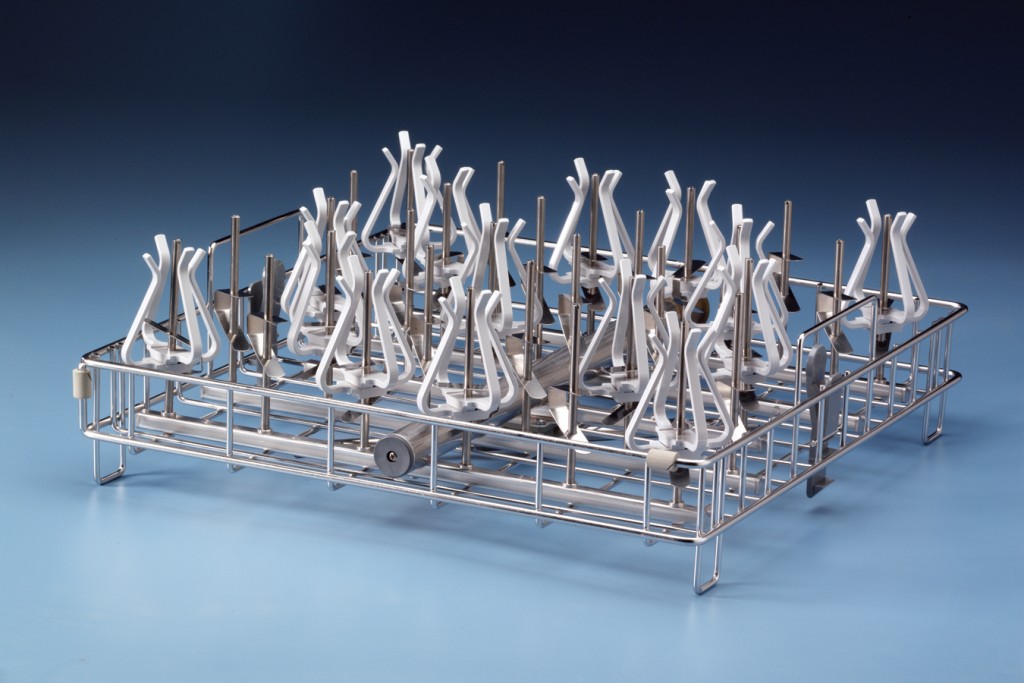

Good - Mangansese Greensand Filter Systems

Better - Terminator Multi Function Filter Systems

One of the first types of filters to be used to treat water was the greensand filter. The active material in greensand is glauconite. Glauconite is a green clay mineral that contains iron and has ion exchange properties. Glauconite often occurs mixed with other material as small pellets, thus the name greensand. The glauconite is mined, washed, screened, and treated with various chemicals to produce a durable greenish-black product that has properties that allow it to adsorb soluble iron and manganese.

As water is passed through the filter, soluble iron and manganese are pulled from solution and later react to form insoluble iron and manganese. Insoluble iron and manganese will build up in the greensand filter and must be removed by backwashing. Backwashing should be done regularly twice a week or as recommended by the manufacturer.

Eventually the greensand must also be regenerated by washing with a permanganate solution. Regeneration will leave the greensand grains coated once again with a manganese material that adsorbs soluble iron and manganese. Frequency of regeneration will depend on the level of iron, manganese, and oxygen in the water and the size of the filter. The manufacturer's recommendations should be followed.

Most greensand filters are rated to be effective treating water with iron concentrations up to 10 ppm. Because some greensand filters are not rated this high, the manufacturer's recommendations should always be checked. The acidity or pH of the water will influence the ability of the filter to remove both iron and manganese. If the pH of the water is lower than 6.8, the greensand will probably not adequately filter out the iron and manganese. The pH can be raised above 7.0 by running the water through a calcite filter.

Regular backwashing is essential for effective filter performance and require flow rates that are often three to four times the normal household useage rate. A backwash rate of about eight gpm/square foot of filter bed is recommended. If the household system cannot support the needed flowrate for adequate backwashing, poor filter performance and failure are likely.

Chlorination Oxidation Plus Filtration

Chemical oxidation followed by filtration is the accepted method of iron and manganese removal when concentrations are greater than 10 ppm. There are a number of strong oxidants that have been used in this procedure; however, chlorine is generally used in household systems Refer to the Chlorination circular in the Treatment Systems for Household Water Supplies series.

A chlorine solution is injected with a chemical feed pump ahead of a sand filter. Soluble iron and managanese begin to precipitate almost immediately after contact with the chlorine solution. However, approximately 20 minutes of contact time is needed for the precipitate to form particles that can be filtered. Often the standard 42 gallon pressure tank used on many household systems will provide the needed contact time if water is forced through the tank. A simple T-connection from the pipeline to the pressure tank will not work, since much of the water bypasses the tank. Additional contact time can be provided by connecting another tank in series or using a plastic pipe coil.

This type of system will remove both soluble and suspended particles of insoluble iron and manganese from the source water. Backwashing the sand filter to remove precipitated iron and manganese is an important part of continued filtration. As with the greensand filter, the system flow rate should be checked to make sure it can provide the needed rates for backwashing.

An additional advantage of using the chlorination system is its bacteriacidal effect. Iron and manganese bacteria, along with other bacteria, are destroyed. Potential clogging problems in the sand filter are eliminated. Chlorination does produce trihalomethanes THM when organic matter is present in the water. THMs are considered to be carcinogenic maximum contaminant level permissible in public water systems is 0.1 parts per million and if necessary can be filtered out with an activated charcoal filter refer to the activated charcoal filtration circular in the Treatment Systems for Household Water Supplies series.

The optimum rate of oxidation of iron and manganese by chlorination is at a pH of about 8.0 and 8.5, respectively. Soda ash injected with the chlorine will increase the pH to optimum levels. Adjusting the pH to alkaline levels also reduces the corrosivity of the water to pipes and plumbing.

Summary of treatment methods for iron and manganese.

Polyphosphate Effective for 0-3 p.p.m.

Ion Exchange softener Effective for 0-10 p.p.m

Most softeners are rated for use at the lower end of the range. Check with the manufacturer.

Greensand Filter Effective for 0-10 p.p.m.

Most greensand filters are rated for use at the upper end of the range. Check with the manufacturer. If water pH is less than 6.8, greensand filters will not perform as rated.

Chlorination and Filtration Effective for 0->10 p.p.m.

Chlorination and filtration will work at all levels of soluble iron; however, it is recommended only for levels above 10 ppm of soluble iron.

Standards for Iron and Manganese Removal Equipment

The Water Quality Association WQA has set voluntary performance standards for oxidative filtration methods. An oxidizing filter shall reduce 10.0 ppm plus or minus 1.0 ppm soluble iron to not more than 0.2 ppm and 2.0 ppm plus or minus 0.2 ppm soluble manganese to not more than 0.05 ppm. A directory of validated equipment that meet these standards is available from WQA, National Headquarters and Laboratory, 4151 Naperville Road, Lisle, IL 60532 708/505-0160.

WQA also recognizes that the following water treatment methods can be used to meet EPA's Secondary Drinking Water Standards for both soluble iron and manganese: 1 oxidizing filters 2 cation exchange and 3 chlorination - precipitation/filtration. Polyphosphate treatment does not meet the drinking water standards, because it ties up iron and manganese but does not remove it. Reverse Osmosis, distillation, Refer to theReverse Osmosis and Distillation circulars in the Treatment Systems for Household Water Supplies series and pressure aeration/filtration are also recognized by WQA as water treatment methods that can be used to meet the iron and manganese drinking water standards.

The consumer should be cautioned to note that different water treatment systems vary considerably in their ability to treat a specific contaminant. Water treatment equipment should be selected only after careful consideration of the water problem and type of equipment to be used for its removal. As a part of the installation procedure, the performance of the equipment should be tested by water analysis. Periodic water analysis is recommended to check for continued equipment performance.

References

Hem, J. D. 1967. Equilibrium chemistry of iron in groundwater. In S. D. Faust and J. V. Hunter 'ed.' pp. 625-643, Principles and applications of water chemistry. John Wiley and Sons, Inc., New York.

Machmeier, R. E. Reviewed 1990. Iron in drinking water, AG-FO-1318. Minnesota Extension Service, University of Minnesota, Agriculture.

O'Connor, J. T. 1971. Iron and Manganese. In M. E. Flentje and R. J. Faust 'ed.' pp. 380-396, Water quality and treatment - a handbook of public water supplies, 3rd Edition. Prepared by The American Water Works Association, Inc. McGraw-Hill Book Co., New York.

Snoeyink, V. L. and D. Jenkins. 1980. Water Chemistry. John Wiley and Sons, Inc., New York.

Water Quality Association. 1988. Recommended industry standards for household and commercial water filters - a voluntary industry standard, S-200. National Headquarters and Laboratory, Lisle, Illinois.

Water Quality Association. 1989. Recognized treatment techniques for meeting the national secondary drinking water regulations with the application of point-of-use systems, R28. National Headquarters and Laboratory, Lisle, Illinois.

--------------------------------------------------------------------------------

AE-1030, February 1992

http://www.ag.ndsu.edu/pubs/h2oqual/watsys/ae1030w.htm

Commentary : This is an excellent article that show many choices in the most common water concerns. We use this article to show unbiased explanations. Most companies may tell you only what they want you to hear. We take a different approach; we give you the information and let you make the best informed decisions.

|

Images are representative of the products. Images may or may not be of the actual product. If it is important e-mail us for an actual image if available.

* Flat Rate UPS shipping when able to ship via UPS and is in the USA excluding Hawaii and Alaska.

Larger Items may not be able to ship via UPS, in that case freight charges will be quoted seperately.

International shipping will be quoted after the order is placed. You will have the opportunity to cancel before we finalize your order.

Terms and conditions

Credit Application

Privacy

Policy

List All Products

|